Indasteri

Boiketsetso

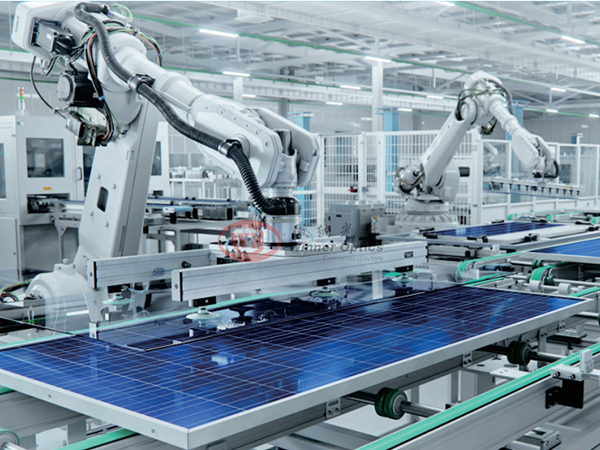

Mekhahlelo ea boemo bo holimo ea motlakase / matsoho e bapala karolo ea bohlokoa lefapheng la liindasteri.Mekhahlelo ena ea maemo e etselitsoe ho tsamaisa lintho hantle le ho beha lintho ka nepo le ka mokhoa o pheta-phetoang, e leng se etsang hore e be tse loketseng lits'ebetso tse fapaneng liindastering tse joalo ka tlhahiso, liroboto, semiconductor le lipatlisiso.

E 'ngoe ea lits'ebetso tsa mantlha tsa maemo a holimo a nepahetseng ke ts'ebetsong ea kopano le ea tlhahiso.Mekhahlelo ena e etsa hore ho be le tlhophiso e nepahetseng le boemo ba likarolo nakong ea kopano, ho netefatsa boleng bo nepahetseng le bo tsitsitseng ba sehlahisoa.Mohlala, tlhahisong ea lisebelisoa tsa elektroniki, methati ena e sebelisetsoa ho beha liboto tsa potoloho, likarolo tsa solder, le lisebelisoa tsa tlhahlobo ka ho nepahala ha boemo ba micron.

Lefapheng la liroboto, ho sebelisoa mekhahlelo e holimo ea boemo bo holimo bakeng sa taolo ea letsoho la liroboto le ho qhekella.Li thusa liroboto hore li etse mesebetsi e rarahaneng e hlokang hore li behiloe hantle, tse kang ho khetha le ho li beha, ho tšoara thepa e bonolo le ho kopanya likaroloana tse nyenyane.Mekhahlelo e fana ka botsitso bo hlokahalang le ho nepahala ho etsa bonnete ba hore moetsi oa ho qetela oa roboto o fihla sebakeng se lakatsehang ka ho pheta-pheta ho phahameng.

Indastering ea semiconductor, moo miniaturization e leng bohlokoa, ho bohlokoa ho beha maemo a holimo ka nepo bakeng sa tlhahlobo ea li-wafer, lithography le lits'ebetso tsa ho paka.Mekhahlelo ena e lumella motsamao o nepahetseng le ho tsamaisana ha li-wafers, limaske le likarolo tse ling, ho netefatsa tlhahiso ea lipotoloho tse kopaneng tsa boleng bo holimo.

Lilaboratori tsa lipatlisiso le nts'etsopele le tsona li rua molemo methating ea maemo a holimo a nepahetseng.Mekhahlelo ena e sebelisoa litekong tse fapaneng tsa mahlale, joalo ka microscope, spectroscopy, le lipatlisiso tsa nanotechnology.Bafuputsi ba ka beha lisampole ka nepo, li-probes le lisebelisoa, ho ba nolofalletsa ho ithuta le ho sebelisa lisebelisoa maemong a manyane le a nanoscale.

Ho feta moo, methati ea boemo bo holimo ea boemo bo holimo e fumana lits'ebetso ho metrology le taolo ea boleng.Li sebelisetsoa ho lekanya li-dimensional, calibration, le tekano ea litsamaiso tsa optical, li-sensor, le lisebelisoa tse ling tse nepahetseng.Mekhahlelo ena e fana ka botsitso bo hlokahalang le ho nepahala ho hlokahalang bakeng sa litekanyo tse nepahetseng le mekhoa ea ho lekanya.

Mabapi le ts'ebetso, mekhahlelo e phahameng ea boemo bo holimo e ka laoloa ka letsoho kapa ka motlakase.Mekhahlelo ea matsoho hangata e sebelisoa lits'ebetsong moo ho hlokahalang liphetoho tse ntle le taolo ea opareitara.Hangata li na le sekala sa micrometer kapa vernier bakeng sa ho bala maemo a nepahetseng le mabili a matsoho bakeng sa liphetoho tsa letsoho.

Mekhahlelo ea ho beha motlakase, ka lehlakoreng le leng, e fana ka taolo e ikemetseng le e hlophisehang.Li ka kopanngoa le mekhoa e meholo ea li-automation 'me tsa laoloa ka li-interfaces tsa k'homphieutha kapa li-programmable logic controllers (PLCs).Mehato ea motlakase e fana ka ho nepahala ho holimo, ho pheta-pheta, le lebelo ha li bapisoa le mekhahlelo ea matsoho, e leng se etsang hore e tšoanele maemo a phahameng a tlhahiso ea lihlahisoa.

Qetellong, methati ea boemo bo holimo ea motlakase / ea matsoho e na le lits'ebetso tse pharalletseng ho li-automation tsa indasteri.Bokhoni ba bona ba ho fana ka boemo bo nepahetseng le bo ka phetoang bo etsa hore e be ba bohlokoa haholo kopanong, liroboto, tlhahiso ea li-semiconductor, lilaboratori tsa lipatlisiso, metrology le taolo ea boleng.Mekhahlelo ena e kenya letsoho ntlafatsong ea tlhahiso, boleng ba sehlahisoa, le katlehong ea liindasteri tse fapaneng, e tsamaisang tsoelo-pele ho automation le theknoloji.